Risk Assessment Control Measures

What’s the point of a risk assessment, unless it helps you to make things safer? Risk Control Measures are all about actually putting safeguards in place and making sure the hazards and risks you’ve discovered have been neutralized.

Your risk assessment will help you to identify hazards and calculate the risk of harm. After that, you need to be able to evaluate existing control measures and assess whether you need to implement new controls. But what kind of controls are there, and how do you get started?

This post will break down Risk Assessment Control Measures into a 5-point Hierarchy of Control:

- Elimination

- Reduction

- Isolation

- Safe Systems of Work (SSW)

- Personal Protective Equipment (PPE)

The Hierarchy of Control

The Risk Assessment Control Measures that you implement to make your workplace safer could include a variety of methods, including removing, repairing or maintaining equipment, introducing and reviewing rules and procedures, and providing appropriate training and supervision.

The 5-point Hierarchy of Control will help you to prioritise which controls will ensure the highest level of safety:

Elimination:

Elimination is the best control measure your business can implement. It’s all about ridding your business of any preventable risks, which could save you a lot of time, money, and effort down the line.

Of course, it’s not possible to completely remove all risks, but you should do what you can where elimination is possible. For example, you can prevent the risk of working at height by providing extendable tools, or arranging to complete tasks at ground level.

Think about what resources you might need to eliminate risks. For the bigger, more dangerous risks, you’ll need to invest more, but it will be worth it in the long run!.

You can see 7 ways to eliminate risks here!

Reduction:

If you can’t eliminate a hazard, the next best approach is to reduce its potential to cause harm. Finding the least harmful option for a necessary procedure will help to minimize any risk.

There are some simple and practical solutions to reducing risk, such as splitting a load into more manageable parts for carrying, substituting a hazardous chemical with a safer alternative, or taking a train to reduce the stress of commuting by driving.

A little research into safer and more efficient alternatives can help your business to run smoothly with minimal risk.

Isolation:

If a hazard can’t be eliminated or substituted, you should try to prevent contact with any potential harm.

This might involve creating a temporary or permanent physical barrier or guard (fence, safety door, bollard) to keep people at a safe remove from a hazard, or using remote control machine operating systems.

You should choose engineering controls that will provide maximum protection to your workforce, which means prioritizing collective protection over that of the individual, where necessary.

Safe Systems of Work (SSW):

Next up, you need to think about how people work, and implement administrative controls to make sure your workplace is using the safest possible working methods and procedures.

Your standard operating procedures and will depend on what type of business you’re running, but could include stopping people from entering loading bays when vehicles are in operating, implementing weather-specific ways of working at height, or using a permit system for electrical work or hotworks.

The rules and systems you have in place should minimize people’s exposure to hazards. Don’t forget to provide people with information and training about how to keep themselves and each other safe, as well as sufficient rest breaks to keep them healthy and alert.

Personal Protective Equipment (PPE)

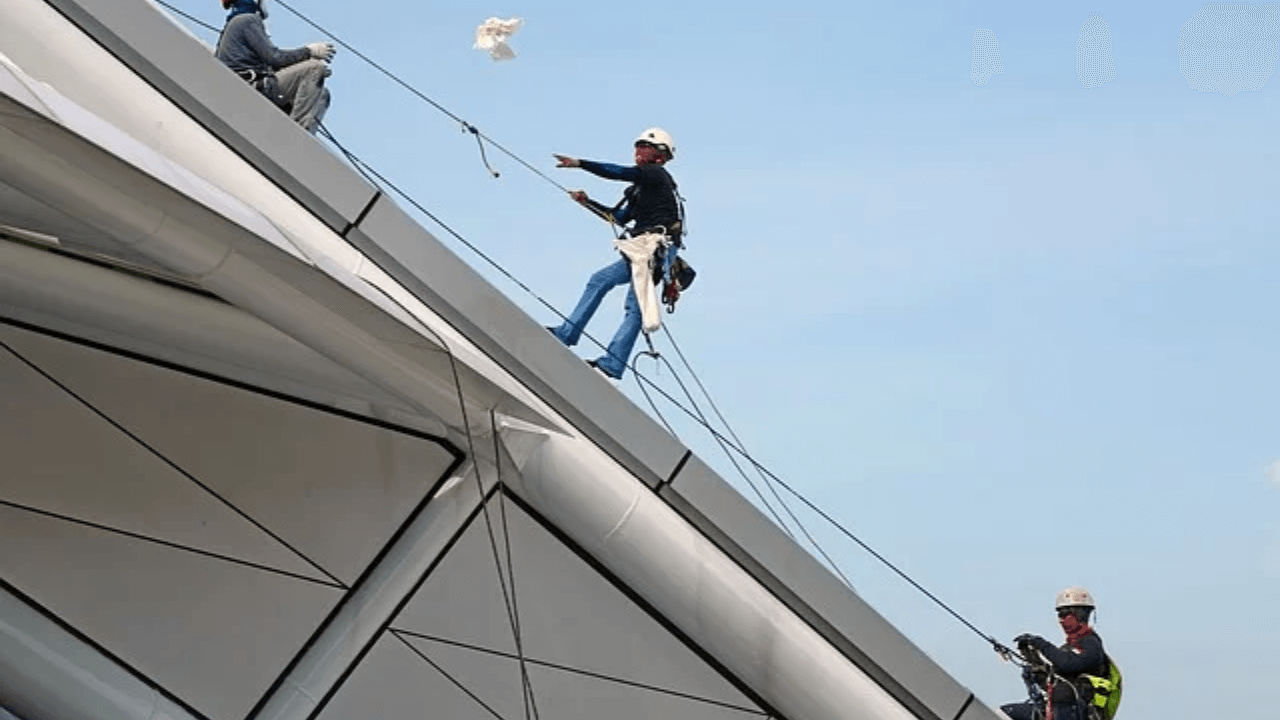

This is the last line of defence after you have done everything you can to eliminate, prevent, and reduce the exposure to risk in your workplace. It involves making sure individuals are kitted out and ready to protect themselves when their work involves some level of inevitable risk.

Depending on the risk, workers should be provided with, and trained in the use of the correct equipment such as ear defenders, eye protection, high visibility jackets, hard hats, overalls, boots, gloves, respiratory protective equipment.

You should view PPE as the final resort in your Risk Assessment Control Measures. It’s really important for the other controls to be implemented first to eliminate the need for added personal physical protection.

If you follow the Hierarchy of Control you should be well protected against the variety of risks you may come up against. Starting with eliminating risks entirely where possible, and then taking measures to reduce, isolate, and minimize the harm of other risks, should massively reduce the need for the final last resort of PPE. However, there’s no denying that sometimes PPE really is the only option when it comes to specific risks. Don’t forget to keep a record of your any controls you implement, communicate information to staff, and provide training, maintenance, and reviews as necessary.

As a business owner, manager, or supervisor, you want to keep your business running safely and efficiently, and sometimes that means making an investment in health and safety control measures.

Risk Assessment Control Measures will help you to prioritise what action to take to eliminate risks where possible, and how to mitigate against harm elsewhere. There are multiple types of control measures your business can follow to help your business stay legal and to ensure everyone and everything is kept safe and sound. Bear in mind that some types of control are much more important than others, and you should always work to hierarchy of control to ensure the best, most sustainable results.

If you need assistance in defining your control measures or have any questions on how to implement these control measures, leave a comment below to share your thoughts!

Comment (1)

Comments are closed.

johfert Bristomm

March 8, 2021Risk assessment is very crucial for identify the compliance for business risk management.

Risk Assessment in Bahrain